Flowrate Out Sensor

To remove the bottleneck associated with the flow paddle, a new flow rate out sensor is suggested with an accuracy of 1 %, making it a game-changer for drilling operations and potentially revolutionizing the drilling industry

Background

The Macondo blowout in 2010 was caused by a series of events, and a main critical factor was the lack of accurate flow measurement as pointed out in the investigation that followed. The commonly used measurement device, the flow paddle, used on Deepwater Horizon, has an accuracy of 10 %. This technology is still preferred due to the lack of alternatives.

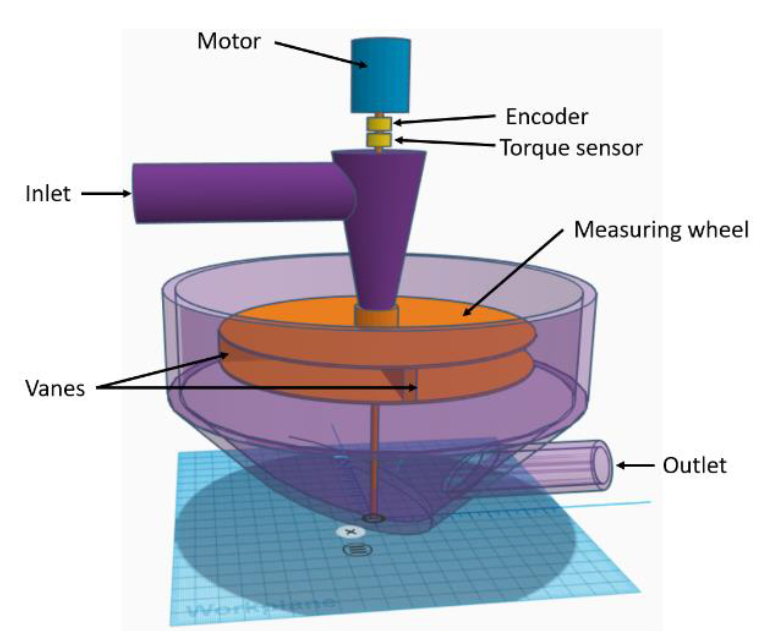

A flowmeter comprising a mass flowmeter and a density measuring apparatus

Initial research using a small-scale apparatus has verified the measurement principle and is applicability for drilling operations, with the required accuracy. The innovation includes sensors for measuring cuttings rate, cutting size distribution, and gas content making it a multi-measurement device requested by the drilling industry for decades. A patent has been granted for Norway in 2021. An international patent application, PCT, is in process.

NORCE has now been awarded a verification project by the Research Council where the main objective is to verify that a semi-full-scale sensor (max 1000 liters per minute (L/min)) has the required sensitivity and precision, with an error at 1% or lower, and with a design that fits existing flowline on representative offshore drilling rigs.

The project started 1st of April 2023.