Drilling of complex well trajectories is often hindered by downhole drill string vibrations and stick-slip. These can lead to drill bit and downhole tool damage, tool-joint and drill string wear possibly leading to a twist-off, or formation damage. Traditional surface‑based mitigation systems often fail to suppress drill‑string‑related stick‑slip or higher torsional modes, especially in extended‑reach drilling.

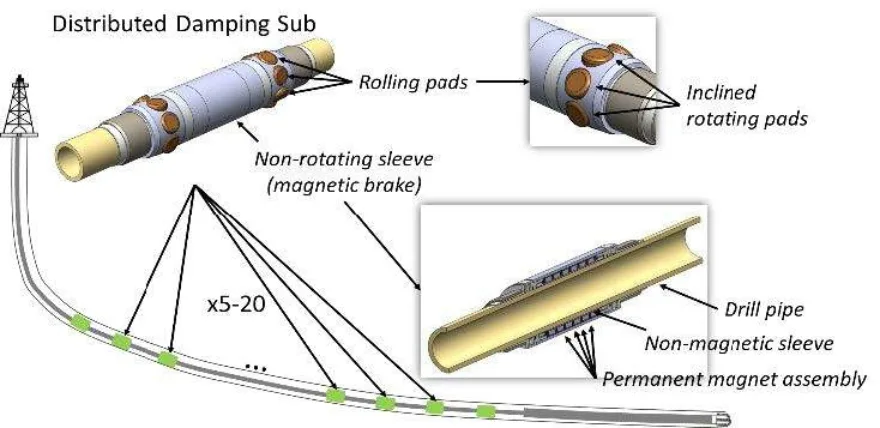

The Distributed Drilling Control (DDC) concept introduces a series of non‑rotating damping subs that can be clamped on along the drill string to eliminate torsional vibrations and improve weight transfer. Each damping sub uses a magnetic braking system that dissipates vibrational energy through eddy currents. The subs also feature an innovative rolling‑pad design that reduces friction along the drill string and decouples axial movement from torsional movement. The technology has potential to provide more efficient operations, with reduced energy consumption and reduced emissions.

Numerical modelling has confirmed the effectiveness of DDS, showing that it eliminates stick‑slip in highly deviated wells, suppresses higher torsional modes, and reduces top‑drive torque by around 40 percent, outperforming conventional surface‑based mitigation systems.

The concept is based on a patented invention developed by Eric Cayeux. In DigiWells’ Vibration Damping we have done research including experimental set-up related to the DDS. Furthermore, simulations showing the advantage with coordinated control of the subs which is not part of this project. In the verification project, the goal is to develop and design DDS from concept to a full-scale field-ready prototype.

The Distributed Damping Sub (DDS) concept