Challenge

Drilling of complex well trajectories is often hindered by downhole drill string vibrations and stick-slip These can lead to drill bit and downhole tool damage, tool-joint and drill string wear possibly leading to a twist-off, or formation damage. Recent advancements in drill string vibration interpretation show that the sources of excitation are not only at the bit but anywhere along the string. Today’s top-drive solutions with soft-torque/soft-speed and Z-Torque help mitigate stick-slip. However, server drill-string vibrations can still occur especially for long wells with long horizontal sections.

Innovation

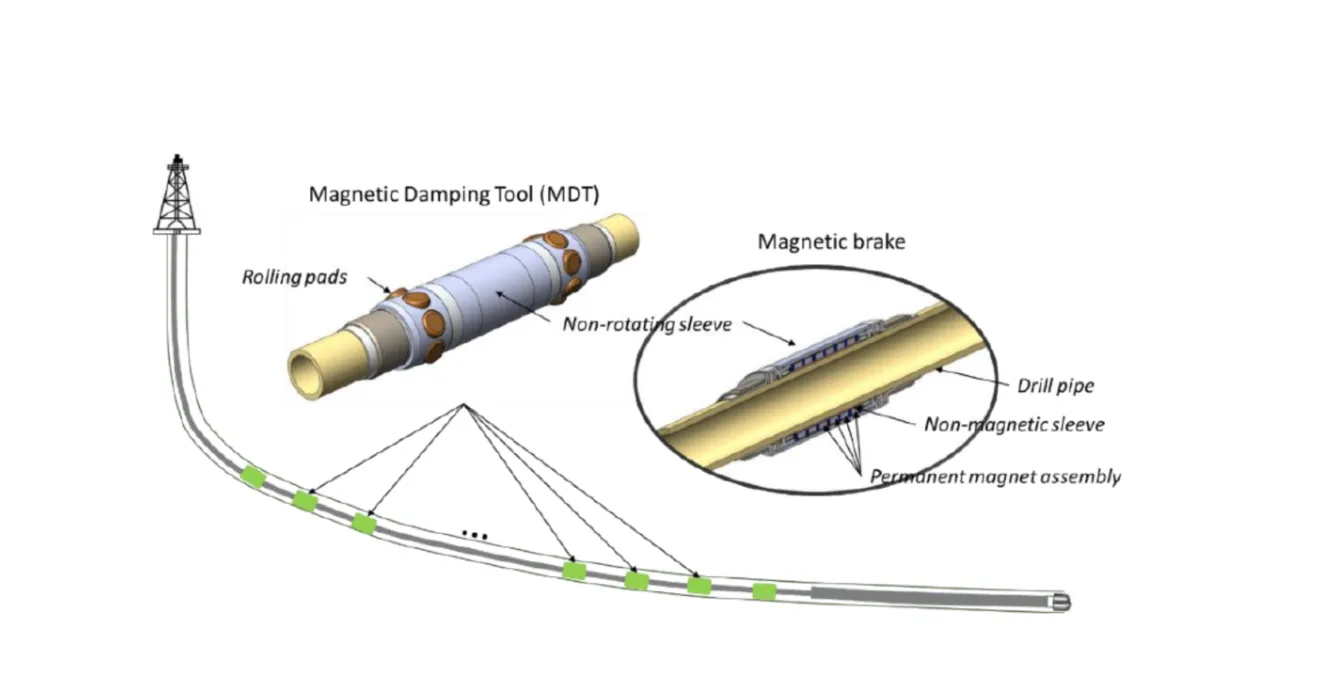

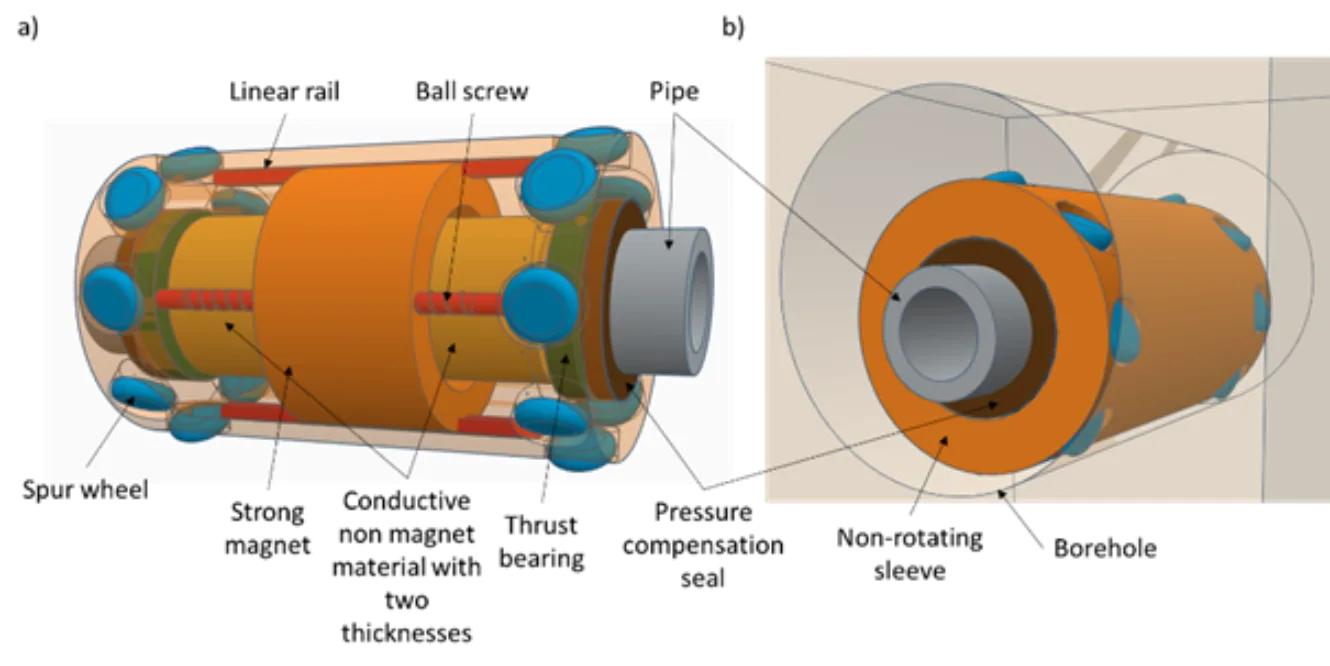

A novel method for mitigating stick-slip vibrations uses magnetic damping elements distributed along the drill string. Each damping sub has a slightly larger diameter than adjacent tool joints, lifting the string off the borehole wall to reduce mechanical friction. Rotary eddy current brakes introduce viscous friction, effectively damping torsional oscillations. To minimize axial drag, the subs move on spur wheels supported by bearings, decoupling axial and rotational motion—key to reducing vibrational excitation. Simulations using a 4-degree-of-freedom torque and drag model confirm performance gains.

A test bench was built to evaluate damping effectiveness. By adjusting the magnetic field, braking force varied linearly with rotational speed. Experiments demonstrated the system’s ability to suppress torsional vibrations and mitigate stick-slip.

The subs also allow active control of damping strength. Simulations show that distributed control algorithms can achieve effective damping with fewer subs. Coordinated sleeve control enables low-amplitude lateral drill-string movement, aiding hole-cleaning while reducing torsional oscillations.

Value

- Vibration can cause damages to drillstring, tool-joints and to expensive downhole equipment. By reducing the vibration such damages can be reduced and even avoided.

- Stable conditions at bit improves drilling efficiency.

- The damping subs reduce the overall required torque at the top-drive and facilitate weight transmission to the bit. Simulations have shown that torque reduction can reach more than 50 percent. A more modest 30 percent decrease is assumed to account for the fact that the tools will not always be lying in part of the well where contacts are significant. This decrease in friction directly affects the electrical energy consumption of the top drive. When drilling long horizontal sections, the savings in cost and CO2 emissions can be significant.

- The concept is patented.

- Enhanced hole cleaning can be achieved by active control of the distributed damping subs to trigger the lateral movement of the drill-string at certain positions which can open the possibility to control wobbling of drill-string.

This work is part of the centres workpackage 5: Drilling automation and autonomy

Next step

- A verification project is started with the aim to build and test full-scale damping tools without active control.

The proposed solution aims at dampening out stick-slip at discrete intervals along the drillstring where stick.slip originates.

Nüsse, Pauline Marie, NTNU. “Decentralized Active Control of Distributed Damping Subs for Stick-Slip Reduction in Drilling”. SPE/IADC Drilling Conference; 2024-03-05 - 2024-03-07

Nüsse, Pauline Marie, NTNU, “Active Control of Distributed Subs With Anti-Slip Logic for Torsional Vibration Damping in Drilling”. ASME 2024 43rd International Conference on Ocean, Offshore and Arctic Engineering; 2024-06-09 - 2024-06-14

A. Ambrus, Ulf Jakob Aarsnes, E. Cayeux, R. Mihai, NORCE, «Modelling and Analysis of Non-Rotating Damping Subs for Removing Torsional Vibrations in Drilling”, ASME 2022. https://doi.org/10.1115/OMAE2022-78339

Nüsse, Pauline Marie, NTNU; Ambrus, Adrian; Aarsnes, NORCE; Aamo, Ole Morten, NTNU: “Decentralized Active Control of Distributed Damping Subs for Stick-Slip Reduction in Drilling”. I: IADC/SPE International Drilling Conference and Exhibition: March 5–7, 2024, Galveston, Texas, USA. Society of Petroleum Engineers 2024 ISBN 978-1-959025-10-8. s. – https://doi.org/10.2118/217676-MS

Nüsse, Pauline Marie, NTNU; Ambrus, Adrian; Aarsnes, NORCE; Aamo, Ole Morten, NTNU: “Active Control of Distributed Subs With Anti-Slip Logic for Torsional Vibration Damping in Drilling”. I: Proceedings of ASME 2024; 43rd International Conference on Ocean, Offshore and Arctic Engineering; Volume 8: Offshore Geotechnics; Petroleum Technology. The American Society of Mechanical Engineers (ASME) 2024 ISBN 978-0-7918-8786-8. s. https://doi.org/10.1115/OMAE2024-123992

Nüsse, Pauline Marie, NTNU; Ambrus, Adrian; Aarsnes, NORCE; Aamo, Ole Morten, NTNU: “Decentralized Active Control of Distributed Damping Subs for Stick/Slip Reduction in Drilling”. SPE Journal 2025 https://doi.org/10.2118/217676-PA

Nüsse, Pauline Marie, NTNU; Ambrus, Adrian; Aarsnes, Ulf Jakob Flø, NORCE; Aamo, Ole Morten, NTNU: “Evaluation of distributed damping subs with active control for stick–slip reduction in drilling”. Geoenergy Science and Engineering 2023 ;Volum 231.(Part A) s. https://doi.org/10.1016/j.geoen.2023.212255

Wilhelmsen, Nils Christian Aars, Nüsse, Pauline Marie, NTNU, Ambrus, Adrian, NORCE, Aamo, Ole Morten, NTNU. “Modeling and detection of slipping in distributed damping subs for drillstring torsional vibration mitigation”. Automatica, 2025. https://doi.org/10.1016/j.automatica.2025.112429

R. Mihai, NORCE, A. Ambrus, NORCE, E. Cayeux, NORCE, “Improving Hole Cleaning by Using Distributed Damping Subs to Control Lateral Oscillations of the DrillString”, IADC/SPE International Drilling Conference and Exhibition, 5-7 March 2024, in Galveston, US. https://doi.org/10.2118/217675-MS

E. Cayeux, A. Ambrus, NORCE, “Self-Attenuation of Drillstring Torsional Vibrations using Distributed Dampers”, SPE Journal, 2023. https://doi.org/10.2118/214675-PA

A. Holsaeter, E. Cayeux, A. Ambrus, R. Mihai, S. Moi, “Experimental Verification of Vibration Mitigation Through a Viscous Damping System Along the Drill String”, SPE Drilling conference 2023,. https://doi.org/10.2118/212521-MS