A new flowmeter concept using a horizontal rotating measuring wheel placed in the return flowline shows to have the potential to reduce the measurement error down to around 1%.

Accurate measurement of the flow rate out of a well during drilling is essential for optimizing drilling performance and ensuring operational efficiency and safety. The Macondo blowout in 2010 was caused by a series of events, and a main critical factor was the lack of accurate flowrate measurement out of the well.

Innovation

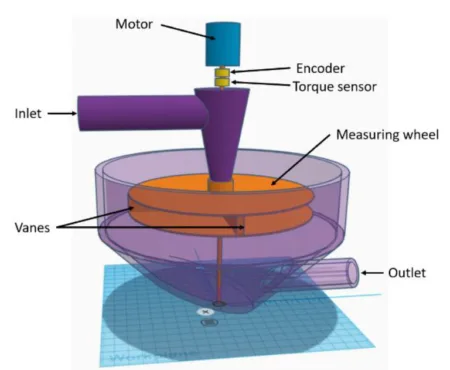

A novel flowmeter concept has been developed using a horizontally rotating measuring wheel placed in the return flowline. The fluid exerts force on the wheel’s vanes, generating a measurable torque that is directly proportional to the mass flow rate. The accuracy of the flow measurement depends on the precision of the torque sensor. Furthermore, the flowmeter is self-cleaning, handles multiphase flow, and has the potential to add sensors for measuring cuttings rate, cuttings size distribution, and gas content.

To validate the concept, a medium-scale prototype was built and tested with various drilling fluids, successfully handling flow rates up to 150 liters per minute, see fig 1. A high-precision vibrating tube Coriolis flowmeter served as the reference standard. Initial proof-of-concept testing on a small-scale setup using drilling fluids with specific gravities of 1.34 and 1.81 demonstrated measurement errors below 5% at moderate flow rates, and less than 1% at higher rates.

Value

Accurate measurement of flow out of the well is essential for safety. Improved precision also reduces uncertainty in increasingly digitalized, automated, and autonomous well construction environments—contributing to lower drilling costs, reduced energy consumption, and safer operations.

The concept is patented.

Status

A small-scale apparatus of a new concept has been built. The results of the tests show significantly improved accuracy of the flowrate out. This research represents a major step towards the development of a full-scale device, supporting an agile development process in the field of digitalization and automation of drilling operations. Industrialization and commercialization are needed for implementation in industry.

Next Step

Find funding to build a full-scale flowmeter and industrialize the new sensor

Illustration of the flowmeter. The innovation includes sensors for measuring cuttings rate, cutting size distribution, and gas content making it a multi-measurement device requested by the drilling industry for decades.