Challenge

The mass density of the drilling fluid is heavily dependent on pressure volume and temperature (PVT). Today, this is normally done manually at the surface. This is a challenge for automated drilling systems.

Innovation

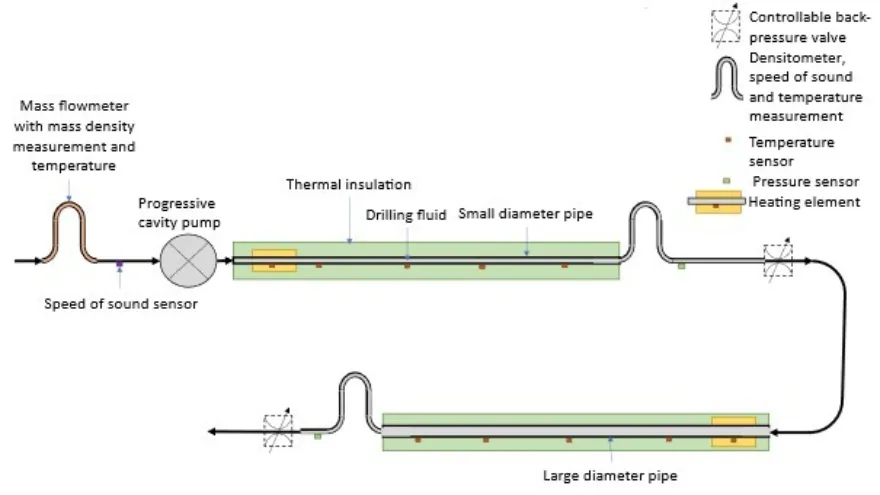

An apparatus has been designed to measure the PVT behaviour of the drilling fluid directly and automatically at different temperatures and pressures at the rig site. The sensor diverts a small portion of drilling fluid through an inline unit with a dosing pump to maintain low flow rates. Two automatic chokes create three pressure levels—atmospheric, 20 bar, and 40 bar—allowing density and speed of sound measurements to calculate compressibility. Heating elements enable readings at three temperatures, improving density extrapolation at elevated conditions. Measurements along the pipes marked with green are added to get specific heat and thermal conductivity of the drilling fluid. While this is often not required for accurate PVT, it is adding information that is very useful for real-time temperature models, see Fig 2.

Value

More accurate determination of key parameters like the drilling fluid’s PVT helps reducing the risk of costly events like stuck pipe, and operations can be run closer to margins without increasing risk. Furthermore, accurate and reliable sensor readings is required by autonomous operations, and the addition of new high-quality sensors is enabling higher degree of automation with fewer humans in the loop. By that, a successful implementation of the PVT sensor will contribute to reducing risk and cost of drilling for oil and gas, geothermal energy, storage of CO2, and more.

The invention is patented.

Status

Experimental work is ongoing, and after which measurements will be combined with calculations to obtain more accurate PVT at downhole conditions than is possible with current methods.

Next Step

If successful, funding is needed for possible adjustments and for building a prototype before industrialization.

This work is organised as a spin-off verification project.

Automatic Measurement of the Dependence on Pressure and Temperature of the Mass Density of Drilling Fluids, E. Cayeux, SPE Journal, https://doi.org/10.2118/204084-PA

Overview of how the Calculation of Dynamic temperature of Drilling Fluids is Closely Linked with Rheology, K. Bjørkevoll, NORCE, Annual Transactions – the Nordic Theology Society, https://doi.org/10.31265/atnrs.776

Using the Quemada rheology model for drilling fluids - practical considerations, K. Bjørkevoll, NORCE, Geoenergy Science and Engineering, https://doi.org/10.1016/j.geoen.2024.213051